Artificial intelligence health diagnostics and management system

Aajoh was a digital health start-up company that used AI to provide e-health services in Nigeria. Aajoh’s mission was to improve the quality of healthcare by using technology to provide access to affordable and accurate diagnostic services. Founding members of Witeroo Inc. were involved in the company’s flagship product, an AI-powered platform patient used to book appointments, track medical history, and receive diagnosis and treatment recommendations from doctors. Featured in publications and online articles, including Ventureburn, Princeton University’s Journal of public and international affairs and Disrupt Africa, Aajoh changed the way people thought about health in Africa and made a positive impact on the lives of its users.

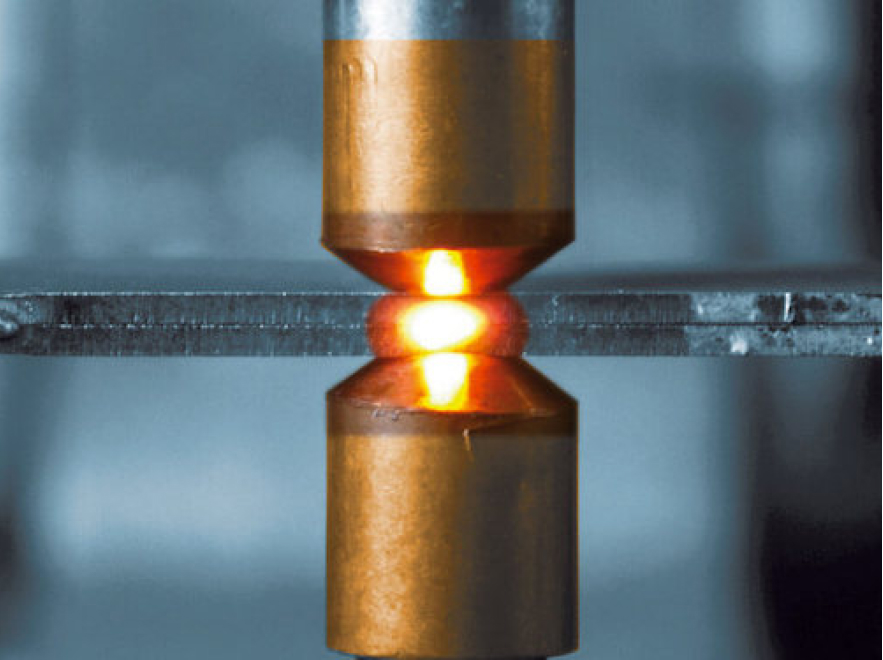

Resistance/projection fastener welding project solutions

As part of a larger engineering team, Witeroo Inc individuals were involved in the controls integration, software and application programming of resistance and projection welding solutions commonly used in the automotive industry for joining of stamped parts. These parts such as sheet metal assemblies often require fastening solutions that are resistant to both the elements and the wear-and-tear of daily use, hence the use of resistance or projection welding applications in automotive plants. The solutions were compact and easy to use, offering unique features like auto weld sequence generation and offline programming, improving productivity and efficiency. They were also modular, with ease of expansion and upgrade, able to weld a wide range of materials and flexible to accommodate changes in production requirements.

10R60/10R80 Input transmission shaft program

The 10R60 and 10R80 input transmission shaft is a joint venture program between Ford and GM for their 10-speed transmission shaft. The goal of the program was to develop an input shaft for a new generation of transmissions that were durable and easier to manufacture than the current design. The new input shaft was made from a high-strength steel alloy and was significantly lighter than previous input shafts. One of Witeroo Inc's members was part of the program team during the automation engineering integration, programming and operations stages of the program featuring state-of-the-art controls and robotics used to produce the shafts with superior quality and efficiency. Applications of the 10R60 shaft can be found in Ford Explorer and Ford Bronco while 10R80 transmissions in F-150, Ford Mustang, and Ranger.

Cloud Infrastructure automation using Terraform on cloud providers.

Using industry-recognized Infrastructure as Code tool Terraform, the provisioning process for your cloud resources across cloud provider platforms can be sped up, avoiding human error and ensuring that the infrastructure is consistent across environments. Terraform’s broad adoption in the cloud computing community is due to its ease of use, strong community support, and rich set of features. The Infrastructure as Code (IaC) approach for managing infrastructure is declarative, reproducible, scalable, and version-able making Terraform an efficient and cost-effective tool for resource automation for your organization, eliminating the need for individual or manual effort. Infrastructure automation will ensure organizational response to change and help achieve greater agility and consistency.

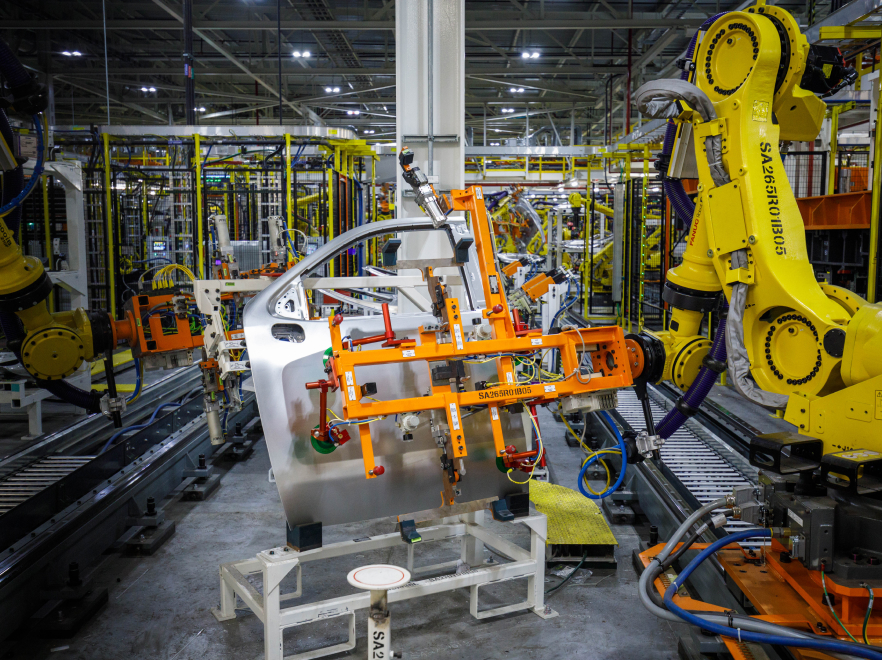

T1-XX flex body welding program

GM's T1-XX program was created to advance the state of the art in body welding for their Oshawa Chevrolet truck facility. The program consisted of two parts: constructing a new body shop and developing new techniques and equipment for body welding. The shop, built using the latest methods and standards featured advanced welding systems from leading industrial automation integrators and solution providers, making it possible to weld a GM truck body with significantly greater accuracy and speed. Witeroo Inc’s direct involvement in the program included controls software design, programming, user/systems acceptance testing, build and software verification and production support. The program is highly sophisticated, involving advanced engineering controls, software, manufacturing and robotics processes. GM T1-XX body welding program is one of the most advanced welding programs in the world, putting Oshawa on the map as a world-class manufacturing center.

Application deployment and container orchestrations with Kubernetes.

For organizations with several containerized applications to manage, Kubernetes is a versatile tool and the gold standard for deployment and management of containerized applications thanks to its robust features and ease of use. The preference for deployment with Kubernetes over traditional deployment can be seen from its ease of deployment at scale, minimal configuration and performance in various environments. A Kubernetes cluster of nodes running one or more pod(s) with one or more container(s) provides all the needed features for the application's performance including networking, storage and more. Kubernetes can be used to automate many of the tasks involved in your organization's application deployment and management, making it an ideal solution for organizations that want to focus on their core business instead of infrastructure management. With Kubernetes, businesses can achieve greater efficiency and flexibility in their application deployments.

Witeroo Inc. v1. web-application

The first version of the Witeroo Inc web application was created to give the company an online presence. Before the development of the application, the company had been in operation, as a consultant and sub-contractor on projects. The need arose for a digital face for the business, highlighting what we do and providing access to company feedback. Version 1 of the application was hosted on AWS cloud, deployed using the platform-as-a-service resource, elastic beanstalk for quick and easy maintenance, monitoring and configuration. To ensure optimal application functionality without any reduced performance from the user standpoint, the environment configuration included automatic scaling to add or reduce the number of instances using scaling criteria based on instance activity metrics. The objectives of the v1 application were met from the presence it created and the number of feedbacks obtained.

Witeroo Inc. v2. web-application

Witeroo Inc.'s version 2 web application was designed for increased engagement with the application, showcasing projects and programs the company has been involved in directly or indirectly and business capabilities. Powered by AWS cloud services, the application was built with scalability, maintainability and agility in mind, with loosely coupled services for ease of changes and updates. New features to the app include content management, subscription management and user management services. The rebranded logo and UI/UX interface were redesigned giving the app a unique layout. Due to the changes needed for an upgrade from v1 to v2, the entire and individual process went through phases of the development lifecycle from planning to implementation. The blog section featured industry-relevant articles and AI-sourced content on technology.